Clear PET Fruit Boxes provide a safe, transparent, and recyclable solution for packaging fresh produce like blueberries, strawberries, and grapes. Their durability, retail-ready design, and eco-friendly properties make them a preferred choice for supermarkets, farms, and food distributors seeking both functionality and sustainability.

Introduction

In today’s food packaging industry, transparency, safety, and sustainability are at the forefront of innovation. Among various packaging solutions, the clear PET Fruit Box has become one of the most popular and reliable options for storing, displaying, and transporting fresh fruits and vegetables. Thanks to the outstanding material properties of PET (Polyethylene Terephthalate), thermoforming technology allows manufacturers to produce durable, safe, and cost-effective packaging that meets the expectations of both retailers and consumers.

This blog will dive deep into the thermoforming process of the clear PET Fruit Box, explore the advantages of PET as a packaging material, and highlight the practical benefits of PET packaging for fruits such as grapes, strawberries, and blueberries. We will also examine trends in disposable Pet Food Packaging Box solutions, the use of Disposable Fruit Packaging, and innovations such as food Grade PET Plastic Blister trays, grape Strawberry Container designs, disposable Clamshell Box formats, custom Molded Fresh Fruit Box solutions, and plastic Fruit Packing Container systems.

PET Material Characteristics

Before diving into thermoforming, it’s important to understand why PET is the preferred choice for fruit packaging. PET (Polyethylene Terephthalate) is a lightweight, durable, and recyclable plastic widely used in the food industry.

Key Properties of PET for Food Packaging:

- Transparency: The clear PET Fruit Box has glass-like clarity that allows consumers to clearly view the contents. This visual appeal improves product visibility and builds consumer trust in product freshness.

- Mechanical Strength: PET provides excellent impact resistance and tensile strength. During transportation and stacking, PET packaging ensures fruits remain protected.

- Food Safety: PET complies with international food safety standards, such as FDA and EU regulations. It is non-toxic, odorless, and suitable for direct food contact.

- Recyclability: PET is one of the most widely recycled plastics, supporting global sustainability efforts. Recycled PET (rPET) can also be used to produce Disposable Fruit Packaging solutions.

- Heat and Chemical Resistance: PET sheets can endure thermoforming processes and resist the natural acids from fruits, ensuring durability and extended shelf life.

The Thermoforming Process of Clear PET Fruit Box

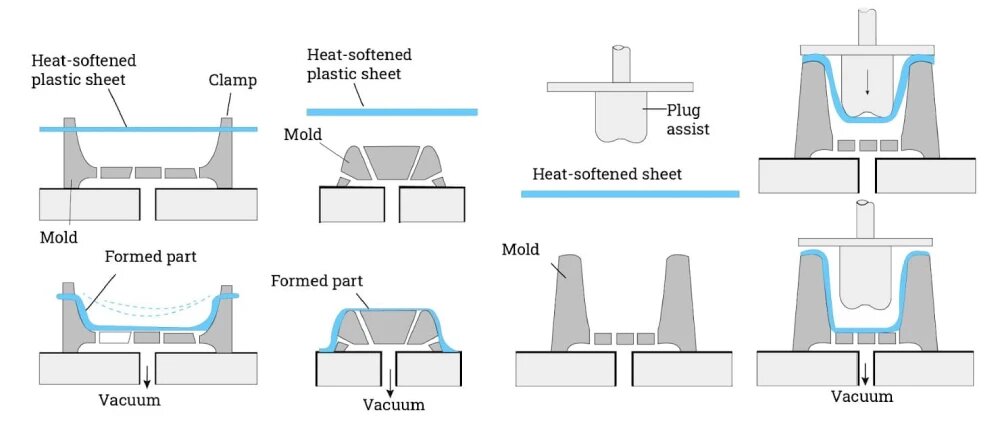

Thermoforming is the most common manufacturing method for producing clear PET Fruit Box designs. It involves heating PET sheets and shaping them into specific packaging formats through molds.

Step 1: Extrusion of PET Sheets

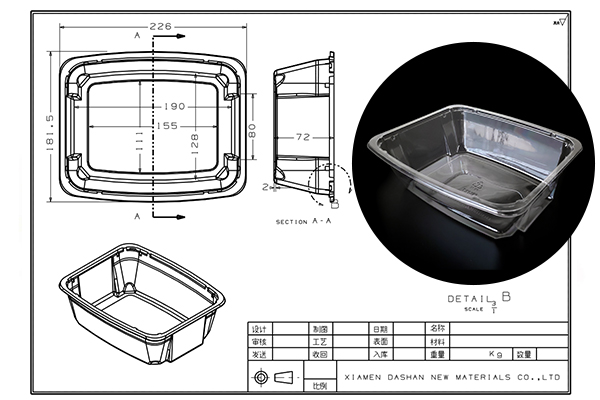

The process begins with PET resin being melted and extruded into flat PET sheets. The thickness of these sheets (usually 0.18mm–1.8mm) depends on the intended application. For food Grade PET Plastic Blister trays, slightly thicker sheets may be required for durability.

Step 2: Heating

The PET sheets are heated to a temperature just below their melting point until they become soft and pliable. At this stage, the sheet is ready to be molded.

Step 3: Forming

Through vacuum or pressure forming, the heated PET sheet is pulled against a mold, shaping it into the desired design of a clear PET Fruit Box, grape Strawberry Container, or disposable Clamshell Box. This step ensures uniform wall thickness and structural integrity.

Step 4: Cooling

Once shaped, the PET packaging is cooled to retain its form. This cooling step enhances rigidity and ensures the packaging can withstand stacking and handling.

Step 5: Trimming and Finishing

After cooling, excess PET is trimmed off. The final packaging can then undergo further finishing, such as perforations, anti-fog coatings, or branding for custom Molded Fresh Fruit Box solutions.

Advantages of Clear PET Fruit Box

The clear PET Fruit Box offers multiple benefits that make it the go-to packaging choice for fruits and vegetables.

1. Transparency for Visibility

The crystal-clear nature of PET allows consumers to see the fruit’s freshness instantly. For retailers, this enhances shelf appeal and boosts consumer confidence.

2. Strength and Protection

PET’s durability ensures that fruits are well-protected against mechanical damage during transportation and handling. For delicate fruits like grapes and strawberries, grape Strawberry Container designs provide cushioning and stability.

3. Food Safety and Hygiene

As a food Grade PET Plastic Blister material, PET guarantees non-toxic, safe, and hygienic packaging that preserves fruit quality without altering flavor.

4. Lightweight Design

The lightweight design of Disposable Fruit Packaging reduces shipping costs while maintaining strength and rigidity.

5. Customization

Through thermoforming, PET allows for a variety of designs, including disposable Clamshell Box, custom Molded Fresh Fruit Box, and vented or perforated options that extend shelf life.

6. Sustainability

PET is widely recyclable, aligning with environmental goals. Using recycled PET helps reduce plastic waste and supports a circular economy.

Applications of PET Packaging in the Fruit Industry

Retail Packaging

Supermarkets and fruit retailers rely heavily on the clear PET Fruit Box for products like strawberries, blueberries, and grapes. The transparency attracts customers while ensuring freshness.

E-commerce Packaging

With the rise of online grocery shopping, lightweight and durable plastic Fruit Packing Container solutions are essential for transporting fresh produce safely. Disposable Pet Food Packaging Box solutions lower shipping costs while ensuring product protection.

Gift Packaging

For premium fruits such as organic strawberries, cherries, and imported grapes, custom Molded Fresh Fruit Box solutions enhance presentation and add value.

Foodservice and Catering

Hotels, restaurants, and catering services use Disposable Fruit Packaging for easy storage and hygienic display of fruits.

Sustainability Trends in PET Packaging

Recyclability

One of the strongest advantages of PET is its recyclability. The clear PET Fruit Box can be collected, recycled, and reprocessed into new products, including rPET packaging.

Lightweight Design for Carbon Reduction

Reducing packaging weight helps cut transportation emissions. disposable Clamshell Box and plastic Fruit Packing Container formats are optimized for both strength and lightness.

Anti-Fog and Breathable Innovations

Modern food Grade PET Plastic Blister designs incorporate anti-fog coatings to maintain visibility even under cold storage, and breathable vents to extend freshness.

Circular Economy Initiatives

Brands are increasingly using recycled PET for Disposable Fruit Packaging, aligning with global sustainability goals.

Market Trends and Consumer Demand

- Consumer Preference: Shoppers prefer transparent packaging like the clear PET Fruit Box because it allows them to judge fruit quality visually.

- Customization Demand: Retailers demand custom Molded Fresh Fruit Box solutions to differentiate their products in a competitive market.

- E-commerce Growth: Lightweight plastic Fruit Packing Container designs are expanding due to the rapid growth of online grocery shopping.

- Premium Packaging: High-value fruits are increasingly being packed in disposable Clamshell Box designs with branded printing for enhanced brand recognition.

FAQ

-

What is a Clear PET Fruit Box?

A Clear PET Fruit Box is a transparent packaging solution made from Polyethylene Terephthalate (PET) plastic, commonly used to store, display, and transport fresh fruits like strawberries, blueberries, and grapes. -

What are the benefits of using PET for fruit packaging?

PET offers transparency, allowing consumers to view the product’s freshness. It is durable, ensuring that fruits remain protected during transportation, and it is recyclable, contributing to sustainability. It is also food-safe, non-toxic, and lightweight. -

Can PET packaging be customized for different fruit types?

Yes, PET can be customized into various designs such as clamshell boxes, molded fresh fruit boxes, and perforated or vented containers to extend shelf life and provide the right fit for different types of fruits. -

How does the thermoforming process work for Clear PET Fruit Boxes?

The thermoforming process involves heating PET sheets, molding them into the desired shape using vacuum or pressure, cooling them to maintain form, and then trimming and finishing the product. This allows for a wide variety of custom shapes and sizes. -

Is Clear PET Fruit Box recyclable?

Yes, PET is one of the most widely recyclable plastics. Clear PET Fruit Boxes can be recycled into new products, supporting a circular economy and reducing plastic waste.

Conclusion

The clear PET Fruit Box represents the ideal balance between functionality, visibility, safety, and sustainability in modern food packaging. Through the thermoforming process, PET sheets can be transformed into diverse packaging solutions such as disposable Pet Food Packaging Box, Disposable Fruit Packaging, food Grade PET Plastic Blister trays, grape Strawberry Container, disposable Clamshell Box, custom Molded Fresh Fruit Box, and plastic Fruit Packing Container formats.

For retailers, manufacturers, and consumers alike, the advantages of PET—transparency, recyclability, strength, and food safety—make it the leading choice for fruit and vegetable packaging. As market trends continue to emphasize sustainability and consumer convenience, the clear PET Fruit Box will remain at the center of packaging innovation for years to come.

References

-

Plastics Industry Association – PET: The Most Recycled Plastic in the World

https://www.plasticsindustry.org/article/pet-most-recycled-plastic-world -

European PET Bottle Platform – PET Sustainability and Recycling

https://www.epbp.org/page/4/recycling -

U.S. Food and Drug Administration (FDA) – Guidance for PET Food Contact Materials

https://www.fda.gov/food/packaging-food-contact-substances-fcs/food-contact-substances-inventory -

Recycling Partnership – PET Plastic Packaging and Circular Economy

https://recyclingpartnership.org/pet-plastics/ -

National Renewable Energy Laboratory (NREL) – Advanced Recycling of PET Packaging

https://www.nrel.gov/news/program/2022/recycling-pet-plastics.html -

Waste & Resources Action Programme (WRAP UK) – Recyclability of PET Packaging

https://wrap.org.uk/taking-action/plastic-packaging

Disclaimer & Copyright Notice

This article is created by the Dashan Packing editorial and research team.All information presented here is for educational and industry reference purposes only.Some data and standards cited in this article are sourced from publicly available materials,official regulatory documents, or third-party publications, which are properly credited where applicable.

All rights to third-party trademarks, images, and content belong to their respective owners.If any copyrighted material has been used inadvertently, please contact us at angel@chndashan.com.We respect intellectual property rights and will promptly remove or revise any material upon verification.